How AI + Liquid 3D Modeling Unlocks Faster Prototyping on Womp

Discover how Womp’s AI-powered Spark and liquid 3D modeling tools help teams prototype faster, iterate visually, and print real objects with ease. Learn practical workflows for 2025.

Discover how Womp’s AI-powered Spark and liquid 3D modeling tools help teams prototype faster, iterate visually, and print real objects with ease. Learn practical workflows for 2025.

Discover how Womp simplifies 3D modeling and printing with browser-based tools, transparent volume pricing, and pro-quality materials. Create, iterate, and print fast.

Learn how to pick the right 3D printing service for your project — from materials & pricing to quality checks and post-processing.

Learn how AI 3D tools and professional 3D printing turn prompts, sketches and images into production-ready parts using Womp’s browser-based workflow.

Learn how to convert sketches, photos, or AI-generated images into 3D-printable models — and order real prints in minutes with Womp’s new “Spark” tools.

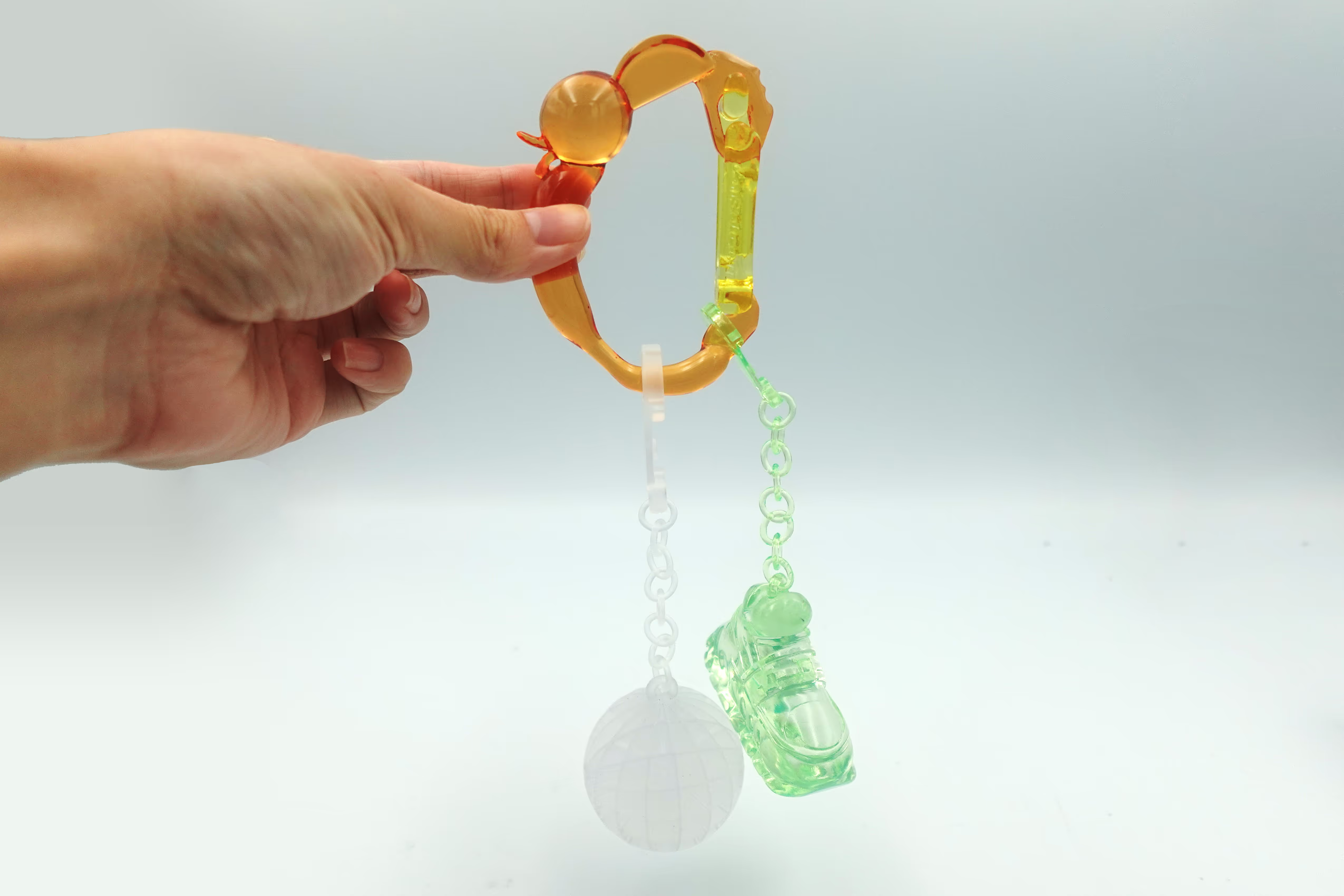

Learn how creators and companies use Womp to rapidly iterate designs using real customer feedback. From prototype adjustments to batch improvements, discover how Womp streamlines decision-driven 3D design.Building a 3D product isn’t just about designing something beautiful — it’s about creating something people love using. The most successful makers treat design as a conversation, not a final output. That’s where Womp stands out: it helps designers iterate fast, test ideas quickly, and use feedback to continuously improve.Whether you're developing accessories, hardware parts, consumer products, or collectable objects, feedback-driven iteration shortens the gap between concept → prototype → final product.Why Customer Feedback Matters in 3D Product DevelopmentIn traditional 3D workflows, revising a model after testing can take days — sometimes weeks. If a customer suggests changes in size, ergonomics, patterning, weight or structural strength, the redesign cycle can slow everything down.With Womp, updates feel fluid:Modify geometry in secondsTest multiple variations quicklyPrint and compare versions the same dayReduce material and development wasteFeedback becomes fuel for improvement — not a delay.Rapid Iteration: Womp’s Real AdvantageWomp’s modeling approach makes design changes effortless. Instead of rebuilding a model from scratch, you can refine shapes as if they were living, editable clay.Example Improvement Loops:FeedbackResponse in WompGrip feels uncomfortableSmooth or reshape surface instantlyPrototype too heavyHollow or reduce volume seamlesslyDetail clarity too lowAdjust resolution + reprint fastClient needs 3 sizesScale and export variations quicklyThis workflow empowers creators to improve real products instead of guessing.Move From Prototype to Final Print — All in One PlaceInstead of exporting files across multiple platforms, Womp lets you design and print within a single pipeline, reducing friction between stages.🔗 3D Printing Workflow → https://www.womp.com/3dprinting sitemapYou can print incremental versions, test them with customers, gather insights, then revise instantly.For Teams: Faster Decisions, Fewer DelaysFeedback loops expand when more eyes are involved — reviewers, clients, engineers, end users. Womp enables collaborative development where everyone can contribute clarity and direction faster.🔗 Explore collaborative tools → https://www.womp.com/womplab sitemap🔗 Connect with experts → https://www.womp.com/expertssitemapWhen ideas evolve instantly, great products emerge sooner.Pricing That Supports Iteration, Not Limits ItMultiple prototypes shouldn't cost a fortune — Womp’s pricing supports creators who need to print in phases, not just one final output.🔗 Simple, scalable pricing → https://www.womp.com/pricing sitemapThis makes feedback-driven production financially accessible for startups, students, and creative studios.Final ThoughtsFeedback is how products grow. With Womp, you don’t just design — you refine, evolve, and improve with every insight. The result is better prints, happier customers, and faster time to final product.🟡 The best feedback loop is the one you can act on today.

Start creating → https://www.womp.com/

Discover how AI powered tools in Womp make 3D creation faster and more accessible. Learn how beginners, designers, and brands use AI to create stunning 3D assets in minutes.

Discover how real-time feedback in Womp transforms the 3D design workflow—reducing iteration time, improving collaboration, and enabling faster concept-to-print results. Learn use cases, tips, and workflow best practices.

Discover how Womp leverages AI to help you generate, refine and print 3D models. Explore real use-cases, workflow tips, and how to go from idea to physical object.

Discover how Womp simplifies the entire 3D printing workflow—from browser-based modeling to print-ready exports and volume-based pricing. Learn best practices to cut costs, iterate faster, and scale your production.

Learn how Womp’s transparent, volume-based 3D printing pricing gives creators and businesses predictable costs, professional-grade prints, and efficiency-driven optimization.Remember when creating 3D models meant spending hours watching tutorials, mastering complex software interfaces, and wrestling with technical concepts that seemed designed to keep outsiders out? Those days are fading fast. We're witnessing a fundamental transformation in how humans interact with creative technology, and it's happening through the simple act of conversation.

Welcome to the era of conversational 3D creation—where your words become objects, your descriptions become designs, and your ideas flow directly from imagination to reality.

The Broken Promise of "Easy" 3D Software

For years, the industry has promised to make 3D creation accessible. Every new tool claimed to be "easier" than the last. And to be fair, modern 3D software like Womp with its innovative liquid 3D modeling approach has dramatically lowered the technical barriers.

But "easier" still meant learning. It still meant understanding primitives, transformations, boolean operations, and spatial relationships. Even with browser-based tools that require no installation, the learning curve persisted.

The real barrier wasn't just technical complexity—it was the interruption of creative flow. Every time you hit a technical roadblock, you had to stop being creative and become a technical problem-solver. That context switch kills momentum, stifles inspiration, and turns what should be joyful creation into frustrating work.

The Conversational Revolution

Enter Womp Spark—an AI assistant that fundamentally changes the equation. Not by making software "easier," but by making it conversational.

Here's the profound shift: instead of learning how to use software, you simply describe what you want to create.

Need a hollow sphere with specific dimensions? Just say it. Want to convert an image into a 3D model? Ask for it. Curious about the best way to prepare a model for 3D printing? Have a conversation about it.

This isn't a chatbot bolted onto traditional software. It's a reimagining of the entire creative interface. The line between getting help, generating content, and refining your work has dissolved into one fluid conversation.

Intelligence That Understands Your Context

What makes Spark genuinely revolutionary is its contextual awareness. This isn't a tool that forgets what you said two messages ago. It's an assistant that maintains the full thread of your creative journey.

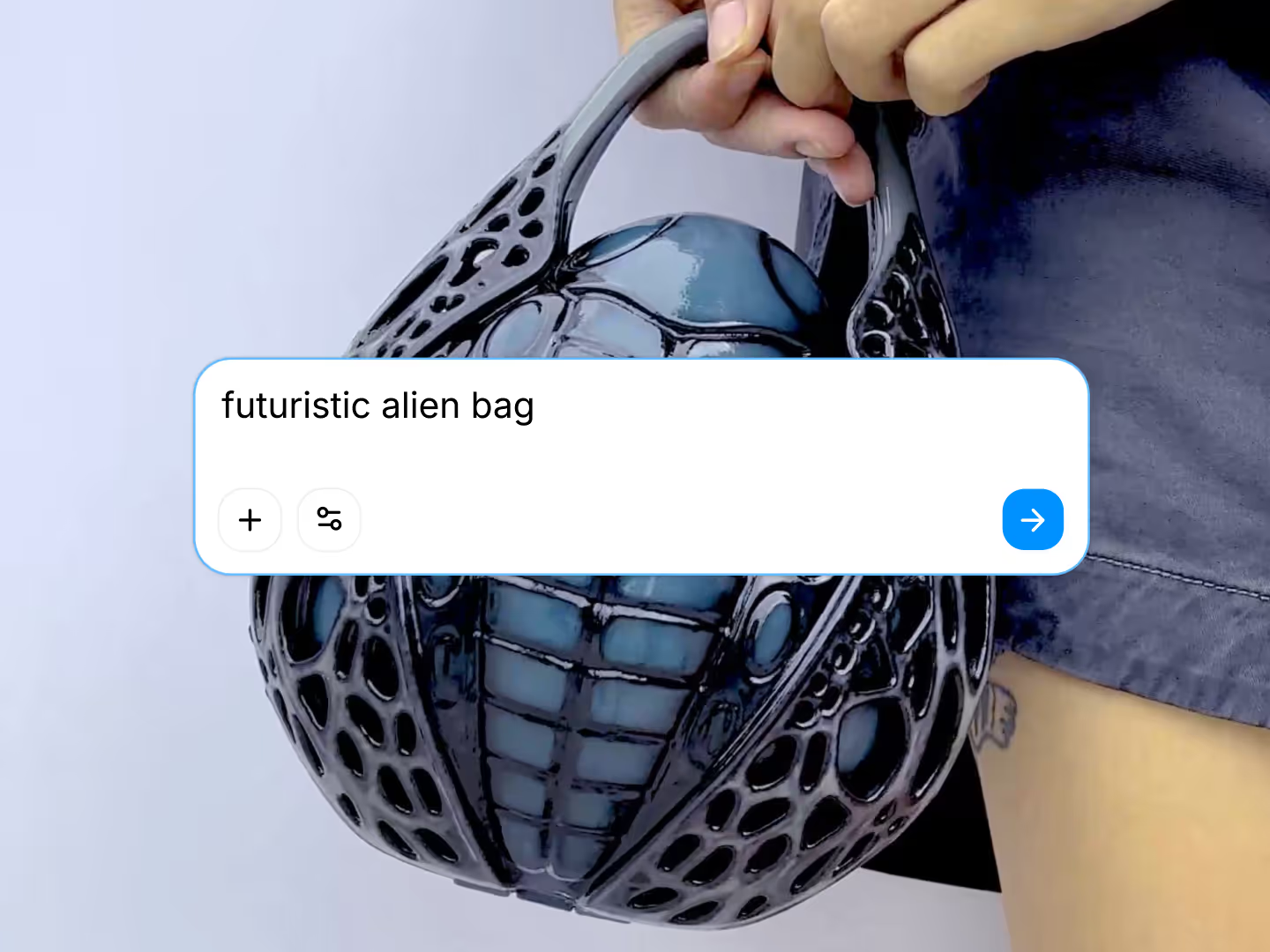

"Create a futuristic coffee mug."

Spark generates several high-quality images. You examine them and continue:

"Make the handle more ergonomic and add subtle geometric patterns."

Spark knows exactly what you're referring to. No need to re-upload images, specify which version, or restart the process. The conversation flows naturally.

"Now convert it to 3D and prepare it for printing."

One request, multiple intelligent actions. Spark generates a 3D mesh, optimizes the geometry for printing, and makes it ready for your Womp 3D printing service. What would have been a multi-step, multi-tool process becomes a single conversational exchange.

The Power of Unified Workflows

Traditional AI tools operate in silos. You use one tool for image generation, another for 3D conversion, a third for mesh optimization, and yet another for printing preparation. Each transition point is an opportunity for friction, errors, and lost creative momentum.

Womp Spark eliminates these silos entirely.

In a single conversation thread, you can:Ask technical questions about 3D modeling fundamentals

Generate concept images using multiple AI models

Convert those images to 3D meshes

Get guidance on optimization techniques

Prepare models for physical production

Troubleshoot any issues that ariseAll without leaving the conversation. All without context switching. All while maintaining creative flow.

From Text to Physical Object in Minutes

The complete pipeline is remarkably streamlined:

Step 1: Describe Your Vision

"I need a decorative wall hook shaped like a tree branch with a modern geometric twist."

Step 2: Refine Through Conversation

Spark generates images. You provide feedback. "More angular geometry. Smoother transitions between the organic and geometric elements."

Step 3: Transform to 3D

"Perfect. Now make it 3D." One click on the "Make 3D" button that appears directly on the image, and you have a printable 3D mesh.

Step 4: Prepare for Production

"Prepare this for 3D printing." Spark optimizes wall thickness, checks for printability, and gets it ready for production.

Step 5: Order Your Print

Click "3D Print," configure your options, and order your physical object. Within days, your conversation becomes a tangible object you can hold in your hands.

The entire process—from initial idea to physical object—takes minutes of your time, not hours or days.

Multiple Models, One Interface

Spark offers access to multiple state-of-the-art AI models, each optimized for different needs:

For Image Generation:Flux Schnell: Fast concept generation (20 credits)

Flux Dev: Enhanced quality for refinement (40 credits)

Flux Pro 1.1: Professional-grade results (120 credits, Pro only)

GPT Image 1: Advanced AI generation (120 credits, Pro only)For 3D Mesh Creation:Trellis3D: Quick 3D generation (20 credits)

Hunyuan3D-2: Enhanced quality (50 credits, Pro only)

Hunyuan3D-3: Premium generation (360 credits, Pro only)The beauty is that you don't need to become an expert in model selection. Spark automatically chooses appropriate models based on your request, or you can specify preferences through natural conversation: "Use the highest quality model for this."

Intelligence in Action: Real-World Applications

The implications of conversational 3D creation extend across industries and use cases:

For Educators

Teachers can generate custom educational models instantly. Need a cross-section of a cell? Describe it. Want a historical artifact reconstruction? Ask for it. The technical barriers that once limited creative teaching are gone.

For Product Designers

Rapid prototyping takes on new meaning when you can iterate through dozens of design variations in an afternoon. Describe a concept, generate it, refine it, print it—all before lunch. The speed of iteration fundamentally changes the design process.

For Makers and Hobbyists

The maker movement promised to democratize manufacturing. But learning CAD software remained a significant barrier. Conversational creation removes that final obstacle. If you can describe what you want to make, you can make it.

For Entrepreneurs

Product development cycles compress dramatically. Test market concepts with custom 3D printed prototypes before investing in tooling. Explore variations without expensive designer time. Move from idea to market validation faster than ever.

The Technical Magic Behind the Conversation

What enables this conversational approach? Several key technological advances:

Context-Aware AI Models: Spark doesn't just respond to individual prompts. It maintains conversational context, understanding references to earlier generations, building on previous decisions, and tracking your creative intent across the entire conversation.

Intelligent Automation: When you say "prepare this for 3D printing," Spark doesn't just execute a script. It analyzes your model, makes intelligent decisions about wall thickness and geometry, and optimizes for successful printing—all automatically.

Seamless Integration: The conversation isn't separate from your work—it's woven into your Womp workspace. Generated content appears with direct action buttons: "Make 3D," "Import to Scene," "3D Print." No manual file management or workflow choreography required.

Smart Defaults with Override Capability: Spark makes intelligent choices about models, settings, and optimizations, but you can override anything through conversation. It's automation that augments expertise rather than replacing it.

Accessibility Meets Power

One of Spark's most compelling aspects is its tiered accessibility:

Free Users get daily credits for experimentation and learning. This isn't a limited trial—it's permanent access to AI-powered creation.

Pro Users receive substantial monthly credit allocations plus access to premium models and features. The Pro subscription unlocks the full power of AI-assisted creation.

Credit Purchases are available to everyone without requiring subscriptions. Need credits for a specific project? Buy exactly what you need.

This model ensures that AI-powered creation isn't locked behind expensive enterprise pricing. It's genuinely accessible to students, educators, hobbyists, and professionals alike.

The Human Element Remains Central

Here's what's crucial to understand: AI doesn't make creative decisions. You do.

Spark executes your vision with speed and precision, but the vision itself remains entirely human. You decide what looks right, what communicates effectively, what solves the problem at hand.

This is augmentation, not replacement. The 3D design process still requires taste, judgment, and creative thinking. What's changed is the execution speed and the elimination of technical barriers.

You spend more time on creative decisions and less time on technical implementation. That's the real value proposition.

Beyond Generation: A Complete Creative Assistant

While AI generation gets the headlines, Spark's role as a knowledge assistant is equally transformative.

Working on a complex project and hit a roadblock? Ask Spark. It can explain Womp's unique features, guide you through export processes, help troubleshoot issues, and suggest workflow improvements—all in natural conversation.

This unified approach means you're never alone in your creative process. Technical questions, creative generation, optimization guidance—all available in one conversation, maintaining perfect context.

The Future is Already Here

We're not describing some distant future possibility. This technology exists today, accessible through any web browser, requiring no special hardware or software installation.

The barriers to 3D creation haven't just lowered—they've fundamentally changed form. Instead of learning complex software, you're having a conversation. Instead of mastering technical details, you're describing creative intent.

And perhaps most importantly, instead of choosing between ease of use and powerful capabilities, you get both.

Getting Started with Conversational Creation

The entry point couldn't be simpler:Visit womp.com and create a free account

Open Womp Spark in the right sidebar or dedicated AI page

Start a conversation: describe what you want to create

Refine through natural conversation

Use the direct action buttons that appear on generated content

Import to your scene and continue workingThat's it. No tutorials required. No manual to read. Just your ideas and an AI assistant ready to help execute them.

The Bigger Picture: Democratization Through Conversation

What we're witnessing extends beyond 3D creation. It's a fundamental shift in how humans interact with complex technology.

For decades, using powerful software meant learning specialized interfaces, memorizing commands, and thinking in terms of tool capabilities rather than creative intent.

Conversational interfaces flip this equation. The software learns to understand human intent. The burden of translation from creative vision to technical execution shifts from human to machine.

This isn't dumbing down—it's a sophisticated translation layer that makes power accessible. Professional designers can work faster. Beginners can create immediately. The gap between them narrows dramatically.

Why This Matters Now

We're at an inflection point in creative technology. The tools exist. The AI models work. The workflows are proven. But widespread adoption requires one crucial element: removing friction.

Womp Spark represents that friction removal. It's the interface that makes AI-powered 3D creation feel natural rather than foreign, conversational rather than technical, empowering rather than overwhelming.

The question for creative professionals isn't whether to adopt these tools—it's how quickly. The competitive advantage goes to those who embrace conversational creation first, who learn to articulate their creative intent clearly, who leverage AI to amplify rather than replace their capabilities.

For everyone else—students, hobbyists, entrepreneurs, educators—this is simply an invitation. The tools that were once reserved for specialists are now available to anyone who can describe what they want to create.

The Creative Process Reimagined

Perhaps the most profound impact is on the creative process itself.

Traditional 3D workflows are linear: concept, modeling, refinement, export, production. Each stage has distinct tools and skills.

Conversational creation makes this fluid. You're constantly moving between ideation and execution, between conversation and creation. Generate an image, get feedback, refine it, convert to 3D, optimize, iterate—all in one flowing conversation.

This fluidity matches how humans actually think creatively: non-linearly, iteratively, with frequent pivots and refinements.

Your Ideas Are Waiting

The barrier between imagination and creation has collapsed. What you can describe, you can create. What you can envision, you can hold in your hands.

This isn't hyperbole—it's the reality of conversational 3D creation today.

The question is no longer "Can I create this?" but rather "What do I want to create?"

Your ideas are waiting. Womp Spark is ready to help bring them to life.Ready to experience conversational 3D creation? Start your journey at womp.com and open Womp Spark today. Your first conversation with the future of 3D design is just a message away.

Remember when creating 3D models meant spending hours watching tutorials, mastering complex software interfaces, and wrestling with technical concepts that seemed designed to keep outsiders out? Those days are fading fast. We're witnessing a fundamental transformation in how humans interact with creative technology, and it's happening through the simple act of conversation.

Welcome to the era of conversational 3D creation—where your words become objects, your descriptions become designs, and your ideas flow directly from imagination to reality.

The Broken Promise of "Easy" 3D Software

For years, the industry has promised to make 3D creation accessible. Every new tool claimed to be "easier" than the last. And to be fair, modern 3D software like Womp with its innovative liquid 3D modeling approach has dramatically lowered the technical barriers.

But "easier" still meant learning. It still meant understanding primitives, transformations, boolean operations, and spatial relationships. Even with browser-based tools that require no installation, the learning curve persisted.

The real barrier wasn't just technical complexity—it was the interruption of creative flow. Every time you hit a technical roadblock, you had to stop being creative and become a technical problem-solver. That context switch kills momentum, stifles inspiration, and turns what should be joyful creation into frustrating work.

The Conversational Revolution

Enter Womp Spark—an AI assistant that fundamentally changes the equation. Not by making software "easier," but by making it conversational.

Here's the profound shift: instead of learning how to use software, you simply describe what you want to create.

Need a hollow sphere with specific dimensions? Just say it. Want to convert an image into a 3D model? Ask for it. Curious about the best way to prepare a model for 3D printing? Have a conversation about it.

This isn't a chatbot bolted onto traditional software. It's a reimagining of the entire creative interface. The line between getting help, generating content, and refining your work has dissolved into one fluid conversation.

Intelligence That Understands Your Context

What makes Spark genuinely revolutionary is its contextual awareness. This isn't a tool that forgets what you said two messages ago. It's an assistant that maintains the full thread of your creative journey.

"Create a futuristic coffee mug."

Spark generates several high-quality images. You examine them and continue:

"Make the handle more ergonomic and add subtle geometric patterns."

Spark knows exactly what you're referring to. No need to re-upload images, specify which version, or restart the process. The conversation flows naturally.

"Now convert it to 3D and prepare it for printing."

One request, multiple intelligent actions. Spark generates a 3D mesh, optimizes the geometry for printing, and makes it ready for your Womp 3D printing service. What would have been a multi-step, multi-tool process becomes a single conversational exchange.

The Power of Unified Workflows

Traditional AI tools operate in silos. You use one tool for image generation, another for 3D conversion, a third for mesh optimization, and yet another for printing preparation. Each transition point is an opportunity for friction, errors, and lost creative momentum.

Womp Spark eliminates these silos entirely.

In a single conversation thread, you can:Ask technical questions about 3D modeling fundamentals

Generate concept images using multiple AI models

Convert those images to 3D meshes

Get guidance on optimization techniques

Prepare models for physical production

Troubleshoot any issues that ariseAll without leaving the conversation. All without context switching. All while maintaining creative flow.

From Text to Physical Object in Minutes

The complete pipeline is remarkably streamlined:

Step 1: Describe Your Vision

"I need a decorative wall hook shaped like a tree branch with a modern geometric twist."

Step 2: Refine Through Conversation

Spark generates images. You provide feedback. "More angular geometry. Smoother transitions between the organic and geometric elements."

Step 3: Transform to 3D

"Perfect. Now make it 3D." One click on the "Make 3D" button that appears directly on the image, and you have a printable 3D mesh.

Step 4: Prepare for Production

"Prepare this for 3D printing." Spark optimizes wall thickness, checks for printability, and gets it ready for production.

Step 5: Order Your Print

Click "3D Print," configure your options, and order your physical object. Within days, your conversation becomes a tangible object you can hold in your hands.

The entire process—from initial idea to physical object—takes minutes of your time, not hours or days.

Multiple Models, One Interface

Spark offers access to multiple state-of-the-art AI models, each optimized for different needs:

For Image Generation:Flux Schnell: Fast concept generation (20 credits)

Flux Dev: Enhanced quality for refinement (40 credits)

Flux Pro 1.1: Professional-grade results (120 credits, Pro only)

GPT Image 1: Advanced AI generation (120 credits, Pro only)For 3D Mesh Creation:Trellis3D: Quick 3D generation (20 credits)

Hunyuan3D-2: Enhanced quality (50 credits, Pro only)

Hunyuan3D-3: Premium generation (360 credits, Pro only)The beauty is that you don't need to become an expert in model selection. Spark automatically chooses appropriate models based on your request, or you can specify preferences through natural conversation: "Use the highest quality model for this."

Intelligence in Action: Real-World Applications

The implications of conversational 3D creation extend across industries and use cases:

For Educators

Teachers can generate custom educational models instantly. Need a cross-section of a cell? Describe it. Want a historical artifact reconstruction? Ask for it. The technical barriers that once limited creative teaching are gone.

For Product Designers

Rapid prototyping takes on new meaning when you can iterate through dozens of design variations in an afternoon. Describe a concept, generate it, refine it, print it—all before lunch. The speed of iteration fundamentally changes the design process.

For Makers and Hobbyists

The maker movement promised to democratize manufacturing. But learning CAD software remained a significant barrier. Conversational creation removes that final obstacle. If you can describe what you want to make, you can make it.

For Entrepreneurs

Product development cycles compress dramatically. Test market concepts with custom 3D printed prototypes before investing in tooling. Explore variations without expensive designer time. Move from idea to market validation faster than ever.

The Technical Magic Behind the Conversation

What enables this conversational approach? Several key technological advances:

Context-Aware AI Models: Spark doesn't just respond to individual prompts. It maintains conversational context, understanding references to earlier generations, building on previous decisions, and tracking your creative intent across the entire conversation.

Intelligent Automation: When you say "prepare this for 3D printing," Spark doesn't just execute a script. It analyzes your model, makes intelligent decisions about wall thickness and geometry, and optimizes for successful printing—all automatically.

Seamless Integration: The conversation isn't separate from your work—it's woven into your Womp workspace. Generated content appears with direct action buttons: "Make 3D," "Import to Scene," "3D Print." No manual file management or workflow choreography required.

Smart Defaults with Override Capability: Spark makes intelligent choices about models, settings, and optimizations, but you can override anything through conversation. It's automation that augments expertise rather than replacing it.

Accessibility Meets Power

One of Spark's most compelling aspects is its tiered accessibility:

Free Users get daily credits for experimentation and learning. This isn't a limited trial—it's permanent access to AI-powered creation.

Pro Users receive substantial monthly credit allocations plus access to premium models and features. The Pro subscription unlocks the full power of AI-assisted creation.

Credit Purchases are available to everyone without requiring subscriptions. Need credits for a specific project? Buy exactly what you need.

This model ensures that AI-powered creation isn't locked behind expensive enterprise pricing. It's genuinely accessible to students, educators, hobbyists, and professionals alike.

The Human Element Remains Central

Here's what's crucial to understand: AI doesn't make creative decisions. You do.

Spark executes your vision with speed and precision, but the vision itself remains entirely human. You decide what looks right, what communicates effectively, what solves the problem at hand.

This is augmentation, not replacement. The 3D design process still requires taste, judgment, and creative thinking. What's changed is the execution speed and the elimination of technical barriers.

You spend more time on creative decisions and less time on technical implementation. That's the real value proposition.

Beyond Generation: A Complete Creative Assistant

While AI generation gets the headlines, Spark's role as a knowledge assistant is equally transformative.

Working on a complex project and hit a roadblock? Ask Spark. It can explain Womp's unique features, guide you through export processes, help troubleshoot issues, and suggest workflow improvements—all in natural conversation.

This unified approach means you're never alone in your creative process. Technical questions, creative generation, optimization guidance—all available in one conversation, maintaining perfect context.

The Future is Already Here

We're not describing some distant future possibility. This technology exists today, accessible through any web browser, requiring no special hardware or software installation.

The barriers to 3D creation haven't just lowered—they've fundamentally changed form. Instead of learning complex software, you're having a conversation. Instead of mastering technical details, you're describing creative intent.

And perhaps most importantly, instead of choosing between ease of use and powerful capabilities, you get both.

Getting Started with Conversational Creation

The entry point couldn't be simpler:Visit womp.com and create a free account

Open Womp Spark in the right sidebar or dedicated AI page

Start a conversation: describe what you want to create

Refine through natural conversation

Use the direct action buttons that appear on generated content

Import to your scene and continue workingThat's it. No tutorials required. No manual to read. Just your ideas and an AI assistant ready to help execute them.

The Bigger Picture: Democratization Through Conversation

What we're witnessing extends beyond 3D creation. It's a fundamental shift in how humans interact with complex technology.

For decades, using powerful software meant learning specialized interfaces, memorizing commands, and thinking in terms of tool capabilities rather than creative intent.

Conversational interfaces flip this equation. The software learns to understand human intent. The burden of translation from creative vision to technical execution shifts from human to machine.

This isn't dumbing down—it's a sophisticated translation layer that makes power accessible. Professional designers can work faster. Beginners can create immediately. The gap between them narrows dramatically.

Why This Matters Now

We're at an inflection point in creative technology. The tools exist. The AI models work. The workflows are proven. But widespread adoption requires one crucial element: removing friction.

Womp Spark represents that friction removal. It's the interface that makes AI-powered 3D creation feel natural rather than foreign, conversational rather than technical, empowering rather than overwhelming.

The question for creative professionals isn't whether to adopt these tools—it's how quickly. The competitive advantage goes to those who embrace conversational creation first, who learn to articulate their creative intent clearly, who leverage AI to amplify rather than replace their capabilities.

For everyone else—students, hobbyists, entrepreneurs, educators—this is simply an invitation. The tools that were once reserved for specialists are now available to anyone who can describe what they want to create.

The Creative Process Reimagined

Perhaps the most profound impact is on the creative process itself.

Traditional 3D workflows are linear: concept, modeling, refinement, export, production. Each stage has distinct tools and skills.

Conversational creation makes this fluid. You're constantly moving between ideation and execution, between conversation and creation. Generate an image, get feedback, refine it, convert to 3D, optimize, iterate—all in one flowing conversation.

This fluidity matches how humans actually think creatively: non-linearly, iteratively, with frequent pivots and refinements.

Your Ideas Are Waiting

The barrier between imagination and creation has collapsed. What you can describe, you can create. What you can envision, you can hold in your hands.

This isn't hyperbole—it's the reality of conversational 3D creation today.

The question is no longer "Can I create this?" but rather "What do I want to create?"

Your ideas are waiting. Womp Spark is ready to help bring them to life.Ready to experience conversational 3D creation? Start your journey at womp.com and open Womp Spark today. Your first conversation with the future of 3D design is just a message away.