Traditional prototyping takes weeks and requires expensive tooling. Modern rapid prototyping services deliver professional-quality physical models in days, enabling faster iteration and better design validation.

Physical prototypes provide insights impossible to achieve through digital models alone, while speed enables more design iterations within project timelines.

Tactile feedback: Hold and interact with designs to understand ergonomics, size relationships, and user experience factors.

Stakeholder communication: Physical models communicate design intent more effectively than renderings or descriptions.

Design verification: Identify problems early when changes are inexpensive rather than after tooling investments.

Days not weeks: Professional SLA printing delivers detailed prototypes in 2-3 business days rather than traditional weeks-long cycles.

Multiple iterations: Fast turnaround enables testing several design variations within single development phases.

Compressed timelines: Accelerated feedback loops reduce overall product development time significantly.

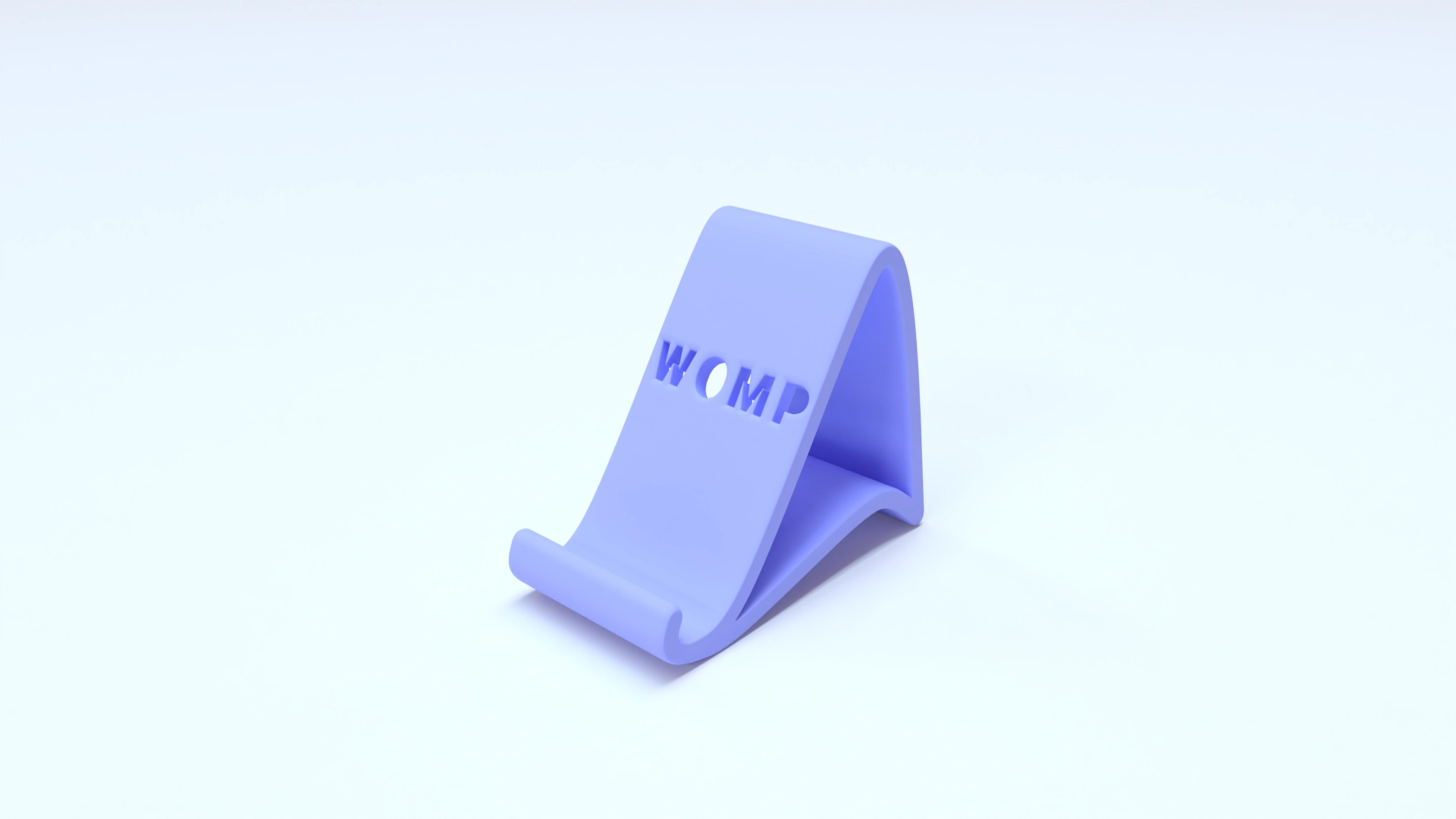

Stereolithography produces smooth, detailed prototypes suitable for professional presentations and functional testing.

Smooth surfaces: Layer-by-layer resin curing creates professional finishes requiring minimal post-processing.

Fine detail reproduction: Capture intricate features, text, and surface textures accurately from digital models.

Dimensional accuracy: Precise reproduction of designed dimensions for fit and function testing.

White prototyping plastic: Professional white finish ideal for presentations, client reviews, and portfolio documentation.

Clear resin options: Transparent materials for display pieces, light studies, and visual impact demonstrations.

Specialized finishes: Matte and glossy options provide appropriate surface characteristics for different applications.

Seamless integration between 3D design and printing eliminates file transfer complications and reduces ordering friction.

Direct integration: Design and order prints within single platform without file exports or format conversions.

Automatic optimization: Built-in print preparation handles technical requirements like wall thickness and structural analysis.

Real-time pricing: Instant cost calculations help balance design complexity with budget requirements.

Pre-print validation: Automatic checking identifies potential printing issues before order placement.

Professional review: Orders undergo quality inspection before printing begins.

Consistent results: Standardized processes ensure reliable quality across multiple orders.

Rapid prototyping economics enable more design testing within reasonable budgets.

Volume-based savings: Bulk discounts available starting at 250 units with scaling discounts up to 12.5% off.

No tooling costs: Eliminate expensive mold or tooling investments for early-stage testing.

Material efficiency: Hollow printing options reduce material usage and costs for larger prototypes.

Design efficiency: Optimize models for printing to balance quality with cost considerations.

Batch ordering: Coordinate multiple design iterations or team members' orders for better pricing.

Size optimization: Adjust prototype scales to achieve testing objectives within budget constraints.

Different sectors benefit from rapid prototyping for specific validation and communication needs.

Consumer goods: Test ergonomics, aesthetics, and user interaction before manufacturing commitments.

Electronics enclosures: Validate component fit, thermal management, and user interface accessibility.

Mechanical assemblies: Check part relationships, clearances, and assembly procedures.

Client presentations: Tangible prototypes enhance proposal presentations and client engagement.

Design validation: Confirm concepts meet requirements before detailed development phases.

Investor demonstrations: Physical prototypes provide credible evidence of development progress.

Student projects: Enable hands-on learning through physical creation and testing.

Research validation: Test hypotheses and concepts through rapid physical iteration.

Curriculum development: Integrate making and testing into educational experiences.

Professional prototyping services handle logistics and quality control to ensure reliable results.

Quick turnaround: Standard processing within 2-3 business days from order confirmation.

Global shipping: Worldwide delivery with tracking and estimated delivery times.

Quality control: Professional inspection before shipping ensures consistent results.

Packaging protection: Professional packaging prevents damage during shipping.

International shipping: Global reach with customs documentation and duty guidance.

Order tracking: Complete visibility into processing and shipping status.

Maximize prototype effectiveness through appropriate design preparation and material choices.

Wall thickness: Maintain minimum 1.2mm thickness for structural integrity and successful printing.

Support considerations: Design orientation and features to minimize support material needs.

Size constraints: Work within printing platform limitations while achieving testing objectives.

Testing priorities: Focus prototype features on critical validation needs rather than comprehensive detail.

Iteration strategy: Plan prototype series to systematically test different design aspects.

Documentation: Record prototype performance to inform subsequent design iterations.

Professional prototyping services maintain consistent quality standards while accommodating design experimentation.

Professional inspection: All prints reviewed before shipping to ensure acceptable quality.

Consistent processes: Standardized procedures ensure reliable results across different orders.

Defect handling: Clear policies for addressing quality issues with photo documentation and resolution procedures.

Process transparency: Clear communication about timelines, capabilities, and limitations.

Technical support: Professional assistance with design optimization and printing requirements.

Continuous improvement: Service evolution based on customer feedback and technology advancement.

Rapid prototyping services transform product development by enabling fast, affordable physical validation. Professional SLA technology delivers presentation-quality results suitable for client meetings, investor presentations, and comprehensive design testing.

Success comes from integrating rapid prototyping into systematic development processes rather than treating it as occasional verification. Plan prototype series that systematically validate different design aspects, and use fast turnaround times to compress overall development cycles.