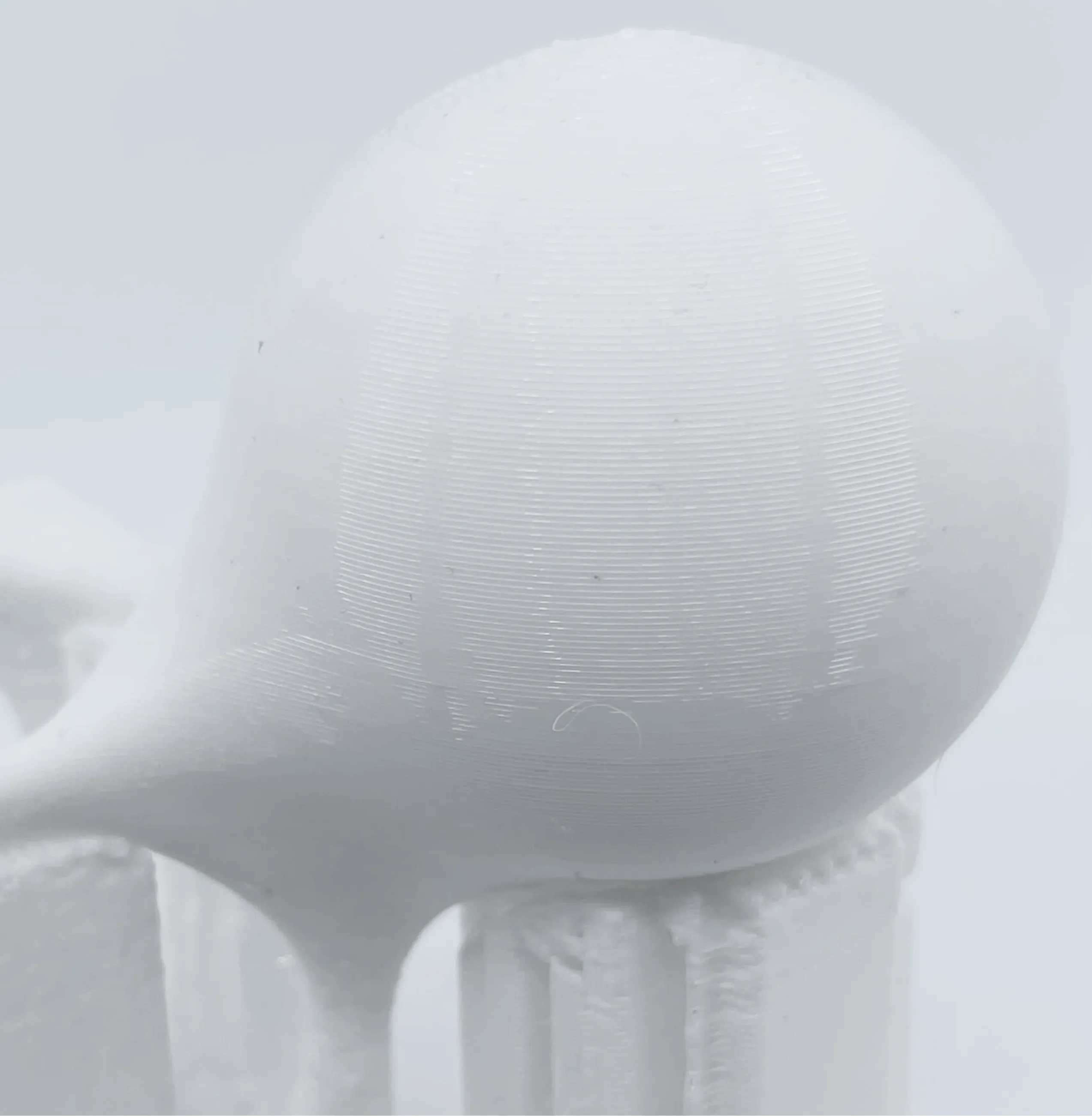

Womp's white prototyping plastic is a beautiful stark white smooth resin printing, that despite its luxurious finish has an incredibly affordable price point.

See how Womp's professional resin printing compares to other 3D printing methods

Womp uses SLA (Stereolithography) technology for 3D printing, offering unmatched detail and smooth finishes. Here’s how it works:

Stereolithography (SLA) creates 3D objects by curing liquid resin with a laser, layer by layer. A computer-guided laser traces each layer's shape onto the resin's surface, causing it to solidify. The platform rises after each layer, allowing the next to form. After printing, the object is cleaned and UV-cured for strength.

Drain holes are important in SLA (Stereolithography) printing because they allow trapped liquid resin to drain out of hollow or enclosed parts of the printed object

Problems without drain holes

Womp Solution

If you choose not to add any drain hole, however, the 3D printing technicians may need to place one themselves to ensure the resin drains properly. This helps create a durable, fully cured model, even if it means adjusting the original design slightly.

The color of Accura White resin can vary slightly and may change over time. It can range from bright white to a soft off-white or light yellow tone.

UV exposure may cause subtle yellowing over time. For best color stability, keep your print out of direct sunlight or consider additional protective coatings.

Each method can improve your print's appearance and durability. Keep in mind that some methods require special care and expertise.

WPP is not food safe without additional treatment. It's also not bio-compatible or skin safe for prolonged contact without protective coating or paint.

For food-related or skin-contact applications, additional treatments or coatings are necessary to ensure safety.

We use high-quality resins for all our prints, including both white and clear options. These resins deliver excellent detail and a professional finish, and are durable enough for both decorative and functional pieces. Learn more about the material here

Once your order is placed, it goes through our quality check process before printing. You'll receive confirmation emails about your order status and tracking information once it ships.

Yes, but only within 1 hour of placing your order. After this window, orders enter production and cannot be cancelled.

After placing your order, prints take 2-3 business days to process. Once processed, shipping time varies by delivery location. You'll receive an estimated delivery timeframe when placing your order. International shipping may take longer due to customs processing.

Design and create in 3D right from your browser. No experience needed, no downloads required.